With the successful development and marketing of mRNA vaccines in recent years, the microfluidic technology behind them has gained great attention. As a frontier technology integrating biology, engineering and computer science, microfluidics has played a great role in the development and application of synthetic biology.

In the process of strain screening and directed evolution, conventional screening methods (e.g. shake flask screening, well plate screening, etc.) have disadvantages such as low throughput and time consuming, while microfluidic platforms are able to rapidly process or control tiny fluids in low-dimensional channel structures in the range of 10 μm to 100 μm, greatly improving screening efficiency and allowing highly reproducible and high-throughput nanoparticle preparation and production.

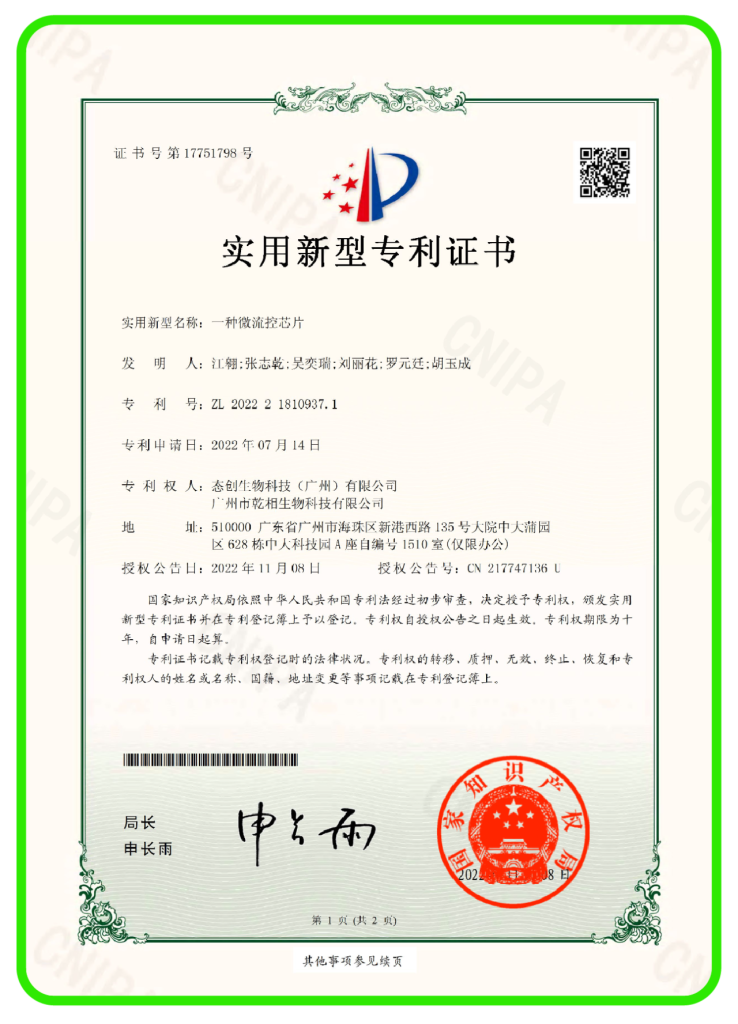

We have developed a microfluidic chip with innovative meaning and core value through the continuous exploration of our research team, and recently obtained a utility model patent certificate for this project.

Stattronics microfluidic platform, also known as multifunctional automated strain mutagenesis and screening platform, is a cutting-edge technology achievement developed by Stattronics in cooperation with several research teams including Nanjing University of Technology and Sun Yat-sen University, which has remarkable features such as high mutagenesis efficiency, fast screening speed, high screening accuracy, diversified screening methods and efficient post-screening identification capability. Through the microfluidic platform of Xiaotron, strain mutants with high capacity, high resistance and good activity can be screened quickly and efficiently, laying a solid foundation for the mass production of substances.

In the process of microfluidic technology application, Xiaotron also upgrades and iterates the platform continuously according to its own needs. For example, the screening of non-resistant strains is one of the difficulties in the field of microfluidics. Traditional chips require multiple steps such as droplet preparation, droplet collection, droplet incubation, droplet re-injection, droplet sorting, etc. The repeated operations are very likely to cause contamination of strains and lead to screening failure.

Xiaochuang thus designed a microfluidic platform and chip that can automatically prepare and sort microdroplets for the purpose, using the principle of density difference between droplet and oil phase to realize strains in droplets to be stored and cultured inside the chip, ensuring that droplet preparation and sorting are done inside the same chip, reducing the steps of droplet cultivation outside the chip, and effectively improving the success rate of screening for non-resistant strains.

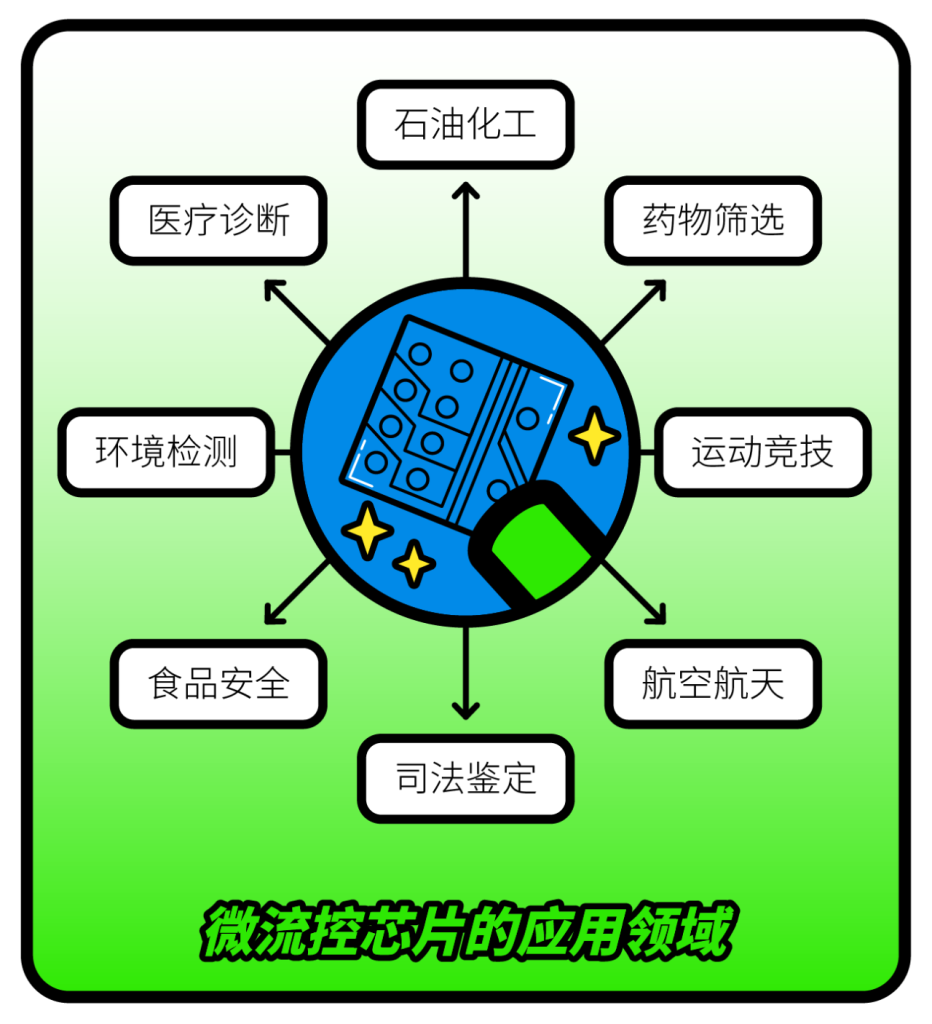

With the development and maturity of the new technology system, microfluidic screening will play an increasing role in synthetic biology and continue to expand the application areas, thus greatly accelerating the innovation and efficient manufacturing of varieties of important products such as bioenergy, biomaterials, chemicals, natural products and biopharmaceutical intermediates.

In recent years, microfluidics has been widely used in biomedicine, such as organ-on-a-chip technology, just-in-time diagnostic (POCT) technology, and biochemical analysis. In addition, in the field of efficacious cosmetics and medical cosmetology, more prominent active substance wrapping and transdermal absorption may be achieved by microfluidic technology, which has great potential for application in whitening and spot removal, filling and anti-wrinkle, and even hair loss.

Microfluidic technology has been systematically implemented and applied in the platform construction of Stato Bio, such as small-molecule organic substances and large-molecule proteins, with excellent results under the support of microfluidic platform. As one of the world's first platforms for the manufacturing of multi-materials, Stato Bio is committed to technology iteration and application innovation, breaking through the industry's mass production bottleneck and iterating green production and supply. At present, there are more than 50 kinds of substances in the library, and we have built our own product capacity to meet the demand of 100+ brands & factories, and directly reach the new demand of "medical, food, beauty and safety" of the people.

Rational transformation is the basis of the synthetic biology industry. Although rational transformation is a commonly used method in the industry, the simple use of this technology leads to high R&D costs, long time consuming and low efficiency. The innovative exploration in the field of microfluidics will promote the technological innovation and industrial change in the industry, and continue to contribute to the green biomanufacturing.

Article source:https://www.sohu.com/a/605037608_121059335